Disclaimer: The information on our website is provided for general information purposes only. We make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information contained on our website for any purpose. Any reliance on such information is therefore strictly at your own risk and we are not liable for any damages or losses arising out of or resulting from your reliance on any information contained on our website.

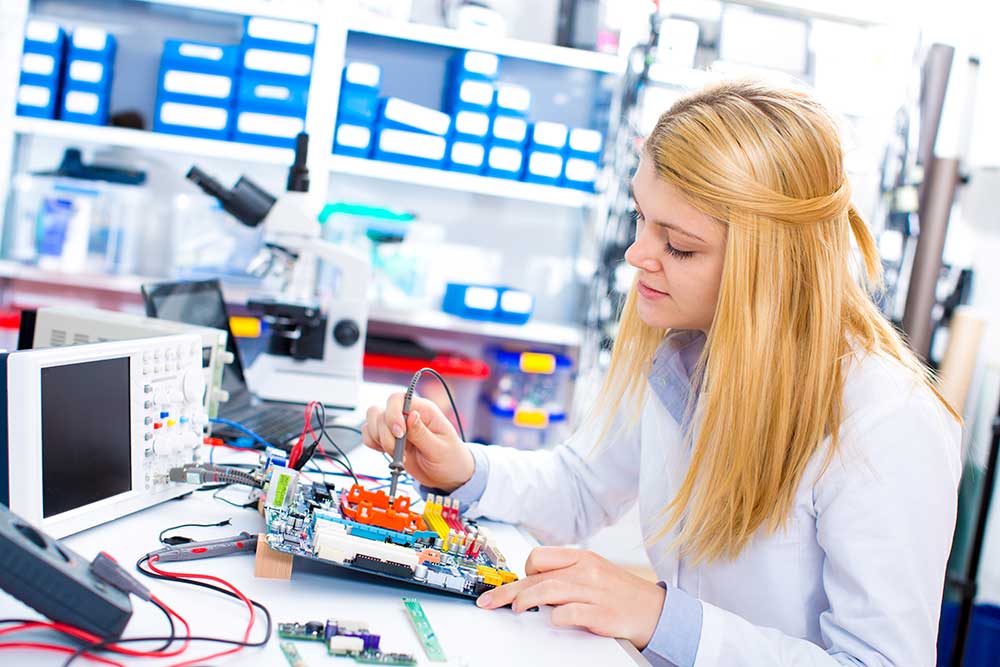

An electro-mechanical technician uses mechanical technology and knowledge of electrical and electronic circuits. Additionally, they operate, test, and maintain robotic, unmanned, automated or electromechanical equipment. They work alongside mechanical and electrical engineers and in various industrial environments to include plastics, energy, computer, communications equipment manufacturing, and aerospace. These techs verify the dimensions of parts by using precision measuring instruments to ensure specifications are met. Watch a video to learn what an electro-mechanical technician does.

How to Become an Electro-Mechanical Tech

An associate’s degree or technical certification is needed for an electro-mechanical technician. Community colleges and vocational trade schools offer courses for this career field. Vocational trade schools place emphasis on skills that local employers look for. Community colleges have similar programs. However, they usually include more liberal arts and theory-based coursework.

Associate’s degrees and higher degree programs are accredited by the ABET with courses that include college-level algebra and trigonometry, along with basic science courses. These ABET-accredited programs offer training in engineering technology specialties. In community college programs, aspirants can focus on areas like mechatronics, electro-mechanics, computer-integrated manufacturing, and industrial maintenance. Electro-mechanical technicians can obtain certification as a means to show professional competence.

Job Description of Electro-Mechanical Technicians

An electro-mechanical technician has the tasks of testing and operating machines in factories or other worksites. This equipment may include aircraft, unmanned submarines, or similar types of equipment for uses in deep-ocean exploration, oil drilling, or hazardous waste removal. These technicians must also read schematics, blueprints, and diagrams to find the sequence and method of assembly of a piece of equipment, machine, or part. He or she verifies parts dimensions using precision measuring instruments to be sure specifications are met.

Electro-mechanical techs may repair and calibrate hydraulic and pneumatic assemblies. These techs perform the installation of electronic hardware and parts and record and analyze test results and prepare written documentation. They should be detail-oriented and have logical thinking abilities. Dexterity is also important because of the need to handle soldering irons and hand tools on small circuits and electronic parts. Considering the benefits when deciding on a career is essential. For example, working alongside engineers is common in this field and this allows continued training. Professionals also continuously learn new technology, benefiting from various industry opportunities. Career advancement is attainable through education and experience.

Electro-Mechanical Technician Career Video Transcript

Have you ever wanted to work hands-on with cutting-edge machines? Electro-mechanical technicians work with some of the most advanced equipment available in the manufacturing industry. Electro-mechanical technicians combine a knowledge of mechanical technology with an understanding of electronic circuits. They test and maintain unmanned, automated, robotic, or electromechanical equipment, including unmanned submarines, aircraft, and related equipment used in oil drilling, deep ocean exploration, and hazardous waste removal. These professionals even read blueprints and diagrams to assemble parts or machines, and verify that specifications are met. They operate machines to make parts, repair and calibrate assemblies and robotic equipment, and conduct tests to assure the quality of operation. In addition, they document test results for reports.

Electro-mechanical technicians work in many industries, including energy, plastics, computer and communications equipment manufacturing, and aerospace. They often spend time both at production sites and in offices. Exposure to hazards from equipment and materials requires that these technicians follow safety procedures on a daily basis. Most work full time on regular shifts, though extra hours may be required for repairs to keep manufacturing operations running. Electro-mechanical technicians typically need either an associate’s degree or a certificate.

Article Citations

Bureau of Labor Statistics, U.S. Department of Labor, Occupational Outlook Handbook, Electro-mechanical Technicians.

National Center for O*NET Development. 17-3024.00. O*NET OnLine.